Introduction:

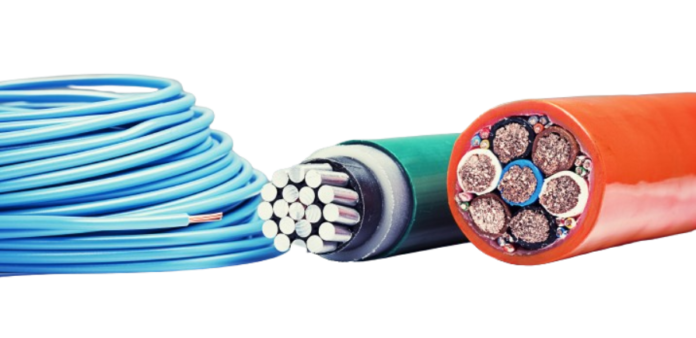

Rubber electrical cables are essential components in various industries, providing reliable transmission of electricity in challenging environments. These cables are known for their unique properties that make them suitable for diverse applications. Understanding these properties is crucial for selecting the right cable for specific requirements. In this guide, we explore nine key properties of rubber electrical cables and their significance in various industrial and commercial settings.

9 Properties of Rubber Electrical Cable

1. Flexibility:

Rubber electrical cables exhibit exceptional flexibility, allowing them to bend and flex without compromising performance. This property is particularly valuable in applications where cables need to navigate tight spaces or undergo frequent movement, such as machinery, robotics, and portable equipment. The flexibility of rubber cables minimizes the risk of damage and ensures smooth installation and operation.

2. Resistance to Abrasion:

Rubber cables feature a durable outer sheath that provides resistance to abrasion and mechanical damage. This property is essential in environments where cables are exposed to friction, impact, or rough surfaces. Whether in industrial settings, construction sites, or outdoor applications, rubber cables maintain their integrity and protect the conductors from external hazards, ensuring long-term reliability.

3. Chemical Resistance:

Another notable property of rubber electrical cables is their resistance to a wide range of chemicals, including oils, solvents, acids, and alkalis. This resistance allows the cables to withstand exposure to corrosive substances without degradation or loss of performance. As a result, rubber cables are suitable for use in industries such as petrochemical, mining, and manufacturing, where chemical exposure is prevalent.

4. Temperature Resistance:

Rubber cables are designed to withstand extreme temperatures, both high and low, without experiencing adverse effects on their performance. This property is critical in applications where cables are exposed to heat sources, cold environments, or temperature fluctuations. Whether in automotive, aerospace, or HVAC systems, rubber cables maintain their electrical properties and mechanical strength across a wide temperature range, ensuring reliable operation.

5. Electrical Insulation:

One of the primary functions of rubber electrical cables is to provide insulation to the conductors, preventing electrical leakage and ensuring safe transmission of power. Rubber materials offer excellent dielectric properties, effectively isolating the conductors and reducing the risk of electrical faults or short circuits. This insulation property is fundamental in electrical distribution, control systems, and power transmission infrastructure.

6. Waterproofing:

Rubber cables are inherently resistant to water and moisture, making them suitable for use in wet or damp environments. The waterproofing property of rubber prevents water ingress into the cable structure, protecting the conductors from damage and maintaining electrical integrity. Whether submerged in water, exposed to rain, or installed in humid conditions, rubber cables offer reliable performance without the risk of moisture-related failures.

7. Flame Retardancy:

Safety is a paramount concern in electrical installations, and rubber cables are designed with flame retardant properties to enhance fire safety. In the event of a fire, rubber materials inhibit the spread of flames and reduce the release of smoke and toxic gases, minimizing the fire’s impact and facilitating safe evacuation. Flame retardant rubber cables are essential in buildings, transportation vehicles, and industrial facilities where fire protection is critical.

8. UV Resistance:

Rubber cables are engineered to withstand prolonged exposure to ultraviolet (UV) radiation from sunlight without degradation or loss of performance. This UV resistance property ensures the longevity of cables installed in outdoor environments, such as solar power systems, outdoor lighting, and telecommunications infrastructure. By resisting UV damage, rubber cables maintain their structural integrity and electrical properties, even in harsh sunlight conditions.

9. Environmental Compatibility:

Rubber electrical cables are environmentally friendly materials that comply with regulatory standards for sustainability and ecological impact. These cables are free from harmful substances such as lead, mercury, and halogens, making them safe for human health and the environment. Additionally, rubber materials are recyclable, reducing waste and promoting resource conservation. As organizations prioritize green initiatives and environmental stewardship, the use of eco-friendly rubber cables aligns with sustainable practices and corporate responsibility goals.

Conclusion:

Rubber electrical cables offer a multitude of properties that make them indispensable in various industrial, commercial, and residential applications. From flexibility and abrasion resistance to chemical resistance and flame retardancy, rubber cables excel in demanding environments where reliability, safety, and performance are paramount. Understanding these key properties enables engineers, contractors, and end-users to make informed decisions when selecting cables for specific requirements, ensuring optimal performance and peace of mind.

Frequently Asked Questions

- What makes rubber electrical cables flexible, and why is flexibility important?

- Rubber electrical cables are flexible due to the elastomeric properties of rubber materials used in their construction. This flexibility allows cables to bend and maneuver easily, making them ideal for installations in tight spaces or applications requiring frequent movement. Flexible cables are also easier to handle during installation, reducing installation time and labor costs.

- How do rubber electrical cables resist abrasion, and why is this important?

- Rubber cables feature a durable outer sheath that provides resistance to abrasion and mechanical damage. This property is crucial in environments where cables are exposed to friction or rough surfaces, such as industrial settings or construction sites. Abrasion resistance ensures the longevity of cables and prevents damage to the conductors, maintaining reliable electrical performance.

- What chemicals can rubber electrical cables resist, and why is chemical resistance significant?

Rubber electrical cables exhibit resistance to a wide range of chemicals, including oils, solvents, acids, and alkalis. This resistance allows cables to withstand exposure to corrosive substances without degradation, making them suitable for use in industries where chemical exposure is prevalent. Chemical resistance ensures the integrity and longevity of cables in harsh environments.

- How do rubber electrical cables perform in extreme temperatures, and why is temperature resistance important?

- Rubber cables are designed to withstand extreme temperatures, both high and low, without compromising performance. This property is critical in applications where cables are exposed to temperature fluctuations or harsh environmental conditions. Temperature resistance ensures that cables maintain their electrical properties and mechanical strength, ensuring reliable operation in diverse settings.

- What role does electrical insulation play in rubber electrical cables, and why is it necessary?

- Rubber electrical cables provide insulation to the conductors, preventing electrical leakage and ensuring safe transmission of power. Rubber materials offer excellent dielectric properties, effectively isolating the conductors and reducing the risk of electrical faults or short circuits. Electrical insulation is fundamental in maintaining the safety and integrity of electrical systems.

- How do rubber electrical cables resist water and moisture, and why is waterproofing important?

- Rubber cables are inherently resistant to water and moisture, making them suitable for use in wet or damp environments. This waterproofing property prevents water ingress into the cable structure, protecting the conductors from damage and maintaining electrical integrity. Waterproofing ensures the reliability of cables in outdoor or humid conditions.

- What makes rubber electrical cables flame retardant, and why is flame retardancy crucial?

- Rubber cables are designed with flame retardant properties to enhance fire safety in electrical installations. These properties inhibit the spread of flames and reduce the release of smoke and toxic gases in the event of a fire, minimizing the fire’s impact and facilitating safe evacuation. Flame retardant rubber cables are essential for ensuring the safety of buildings, vehicles, and industrial facilities.

- How do rubber electrical cables resist UV radiation, and why is UV resistance important?

- Rubber cables are engineered to withstand prolonged exposure to ultraviolet (UV) radiation from sunlight without degradation. This UV resistance ensures the longevity of cables installed in outdoor environments, such as solar power systems or outdoor lighting. UV resistance preserves the structural integrity and electrical properties of cables, even in harsh sunlight conditions.

- Are rubber electrical cables environmentally friendly, and why is environmental compatibility significant?

- Rubber electrical cables are environmentally friendly materials that comply with regulatory standards for sustainability and ecological impact. They are free from harmful substances and are recyclable, reducing waste and promoting resource conservation. Environmental compatibility makes rubber cables a preferred choice for organizations seeking to minimize their environmental footprint and adhere to green initiatives.

![How to Fix [pii_email_e6685ca0de00abf1e4d5] Error Code? [pii_email_e6685ca0de00abf1e4d5]](https://www.techwebtopic.com/wp-content/uploads/2022/02/pii_email_e6685ca0de00abf1e4d5.jpg)