Electronic components come with a plethora of specifications, and selecting the right components for a given application based on these specifications is critical to ensure optimal performance and reliabil

How Component Specifications Can Affect Quality Control

- Ensuring Conformance to Design Intent: Electronic devices are designed with specific requirements and functionality in mind. Deviations from these specifications can cause compromised performance, reliability issues, and even safety hazards.

- Interoperability and Compatibility: Components need to work with one another to ensure the proper device functionality. Electronic component specifications include details about interfaces, signal levels, and communication protocols. Testing electronic components to ensure they adhere to these specifications ensures interoperability and compatibility between different components within a system.

- Manufacturing Consistency: Consistency is crucial for mass production, where large quantities of components are manufactured with minimal variations so that manufacturers can achieve uniformity in their products, minimizing defects and enhancing the efficiency of the manufacturing process.

- Compliance with Industry Standards and Regulations: The electronic industry is governed by many standards and regulations set forth by organizations such as the International Electrotechnical Commission (IEC), Institute of Electrical and Electronic Engineers (IEEE), and others. Electronic component specifications are often aligned with these standards to ensure compliance.

- Traceability and Root Cause Analysis: In the event of a quality issue or failure, traceability is crucial to identify the root cause and implement corrective actions. Electronic component specifications provide a reference point for traceability, enabling manufacturers to investigate and address issues systematically.

Common Electronic Components and the Importance of their Specifications in Quality Control

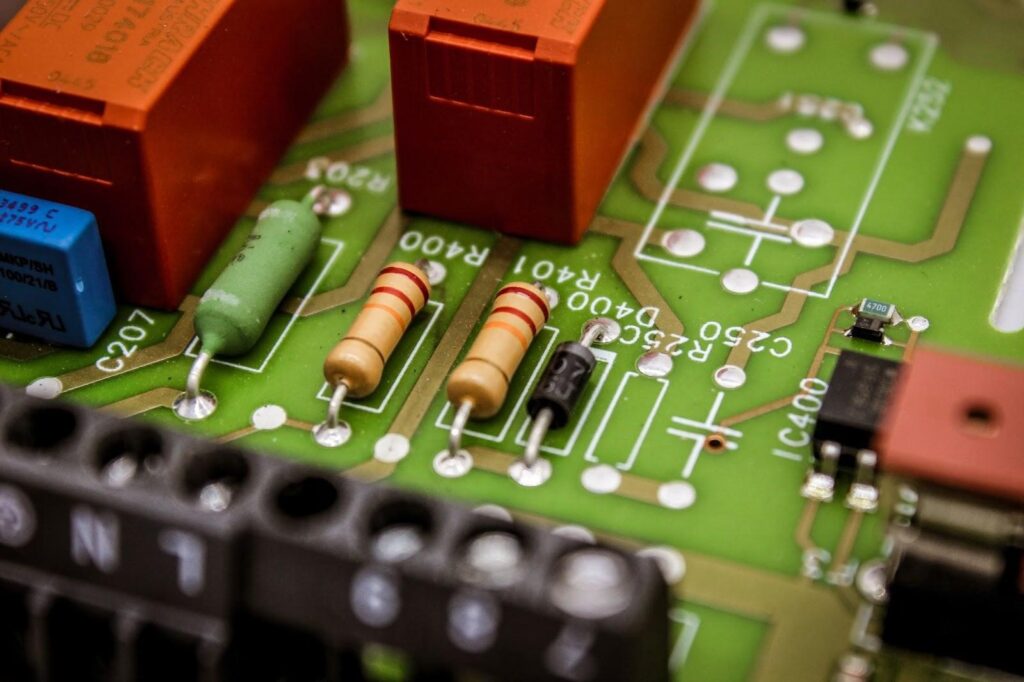

Resistors: The Precision of Ohms

Resistors are fundamental components that regulate current flow within a circuit. The resistance value, denoted in ohms (Ω), is a defining specification. An inaccurate resistance value can disrupt the desired current flow, jeopardizing the functionality of the entire circuit.

For instance, a resistor in a terminal block connector will perform various functions such as signal conditioning, current limiting, impedance matching, and voltage regulation. These are all quite important to ensure that your connector provides proper connectivity. Therefore, the right connector will have resistors capable of reliably meeting these needs over the lifetime of the connector.

In addition to resistance values, it’s essential to consider power ratings for resistors. Power ratings indicate the maximum power a resistor can dissipate without overheating.

Capacitors: Voltage Ratings and Capacitance

Capacitors store and release electrical energy, playing a pivotal role in timing and filtering applications. Their specifications include capacitance (measured in farads) and voltage ratings. A capacitor with an insufficient voltage rating may fail catastrophically, leading to circuit malfunction or damage.

It is also crucial to consider specifications like Equivalent Series Resistance (ESR) and temperature coefficients during quality control. ESR impacts capacitor performance, especially in high-frequency applications, while temperature coefficients ensure stability across varying temperature conditions.

Transistors: Voltage, Current, and Gain

Transistors serve as electronic switches or amplifiers, regulating the flow of current. Voltage and current specifications, along with gain values, define their performance characteristics. An erroneously specified transistor can result in signal distortion, power inefficiencies, or circuit instability. For instance, transistors in surge protectors must meet certain specifications to reliably protect devices from electrical surges.

Temperature ratings for transistors are equally crucial to ensure the transistor operates reliably across the specified temperature range.

Integrated Circuits: Precision in Functionality

Integrated circuits (ICs) are intricate assemblies of multiple electronic components on a single chip. Specifications for ICs encompass power supply requirements, input and output voltages, operating temperatures, and data transfer rates. Failure to adhere to these specifications can lead to IC overheating, data corruption, or even permanent damage.

In addition to the mentioned specifications, parameters like clock frequency, propagation delay, and input/output current capabilities are important during quality control because they directly impact the speed and efficiency of the integrated circuit in a given application.

Potentiometers: Resistance and Angular Precision

Potentiometers (adjustable resistors) play a crucial role in controlling voltage levels within a circuit. Their specifications include resistance values (ohms) and mechanical angles of operation. Incorrect resistance values can skew voltage levels, affecting circuit performance, while imprecise mechanical angles can disrupt signal calibration.

Considering the mechanical aspects, potentiometers may undergo frequent adjustments in certain applications, and ensuring they can withstand mechanical stress is vital for long-term reliability.

Inductors: Maintaining Inductance and Current Ratings

Inductors store energy in a magnetic field and are pivotal in energy storage and filtering applications. Inductance values (measured in henrys) and current ratings define their specifications. Deviations from these values can lead to energy loss, inefficient operation, or even circuit damage.

It’s also essential to assess factors like core material and saturation current during quality control. The core material influences inductance stability, while saturation current determines the maximum current the inductor can handle before losing inductance.

Follow Specifications for Device or Circuit Perfection

In conclusion, the importance of electronic component specifications in quality control cannot be overstressed. The intricate interplay of resistance, capacitance, voltage, current, and various other parameters requires disciplined adherence to the recommended specifications to ensure the functionality and reliability of the device.